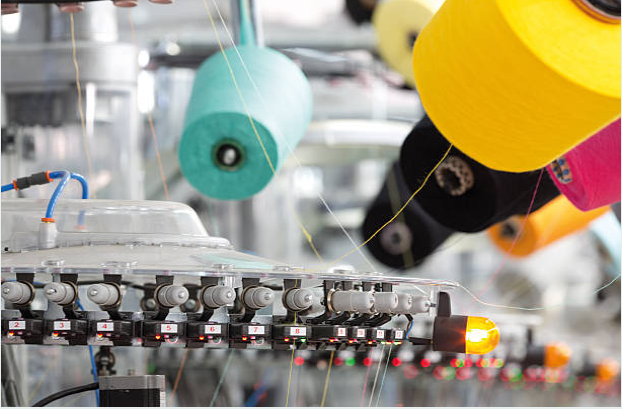

Automation Will be Key to Curbing Rising Costs

August 28, 2018

Today’s apparel, textile and footwear executives are facing significant challenges. Competitive pressures are growing. The need for efficiency and accuracy is intensifying. And with labor shortages looming across China, labor costs are increasing.

As a result, some executives are investing in automation, hoping to capitalize on reductions in cost, waste and delays.

However, as many are finding, robots alone will not yield success. Like any manufacturing revolution, the shift to automation requires preparation, including optimized processes, practices and operational management.

Increasing Pressures to Adapt and Evolve

In the modern, fast-changing global marketplace, competition is greater than ever. And while executives confront the difficulty of capturing and maintaining customer loyalty, they are also facing a wide array of economic challenges.

Most notably, the ever-present challenge of producing higher quality products in less time and with less resources is being amplified by growing labor costs.

For instance, in China, the world’s dominant producer of apparel and footwear, the scarcity of manpower and true artisans has doubled labor costs in the last five years, according to a recent IHS Markit report. Moreover, they are expected to rise another 10 percent this year alone.

Automation: A Growing Competitive Necessity

Consequently, many executives are exploring and embracing automation. In fact, 1.3 million new industrial robots will be installed in factories over the next three years, according to a recent International Federation of Robotics report.

While the initial investment in automation is substantial—one basic sewing robot averages $40,000—the short- and long-term returns can be overwhelming.

For example, consider the manufacturing process of an average shoe, which typically requires 28 separate, manual operations. As more tasks are automated, improvements in accuracy, material savings and productivity are compounded. And with the potential to reduce factory resources by up to 70 percent, executives may be able to recoup their investments within months, not years.

For this reason, in segments such as footwear manufacturing—particularly cutting, sewing, and soling operations—the shift to automation is no longer an option; it is a competitive necessity.

The New Manufacturing “Revolution”

The shift to automation is also part of the natural evolution in apparel, textile and footwear manufacturing, as executives seek more efficient, accurate and dependable methods.

Continuing with the shoe factory example, consider the modern evolution of the basic leather cutting task. In the early 1900s, this task entailed a pattern, knife, and the human eye. By the late 1900s, it still entailed the human eye, but technology had shifted to metal die and a clicking machine.

Today, as a result of automation, the human eye is no longer an essential component. Instead, the task has evolved to feature leather scanning for defects, computer positioning of patterns, and robotic cutting.

The Importance of Preparation in Achieving Maximum ROI

Given the potential competitive, economic, and operational benefits of automation, it is no surprise that we are on the verge of a new manufacturing revolution. However, there’s a catch: investing in robotic technology alone will not significantly improve results.

Like all prior manufacturing revolutions, a shift in technology must be accompanied by a similar shift in organization and operational management.

Looking back to the innovations of Henry Ford and Frederick Winslow Taylor, their success in revolutionizing production would not have been possible without powerful management and a strong layer of organization. The assembly line required calculations to be well balanced and each work station to be intensely studied, fine-tuned, monitored and adjusted in real time.

Such is the case with today’s automation revolution. To deliver optimal efficiency, robots require optimal efficiency at the human level. Therefore, executives must prepare and evolve their operations prior to implementing robotics.

Timing of these efforts is critical, especially given the tremendous capital expense of automating tasks factory-wide. If a factory is not sufficiently Leaned before robots are implemented, ROI can plummet—or worse.

The Path to Success: Three Key Preparation Steps

So what does necessary preparation look like?

Considering the wide array of tasks that must be accomplished, the effort may seem daunting. After all, production flow must be optimized. Cutting, stitching and assembly must be in line and well balanced. Data capture must be organized to maintain process flexibility. Materials and supplies must be fully under control to ensure quality and on-time delivery. Employees and management must be trained and fully committed.

It is a lot, but it can be done. Specifically, with the assistance of process optimization specialists, executives can effectively prepare for automation by completing three key tasks:

- Defining the factory’s needs and most probable evolution in terms of products, lead times, technical options and finishing options.

- Thoroughly analyzing and optimizing current processes by implementing Lean manufacturing principles.

- Planning and engineering implementation and phasing via setup, transition and training.

Optimizing factory processes prior to implementation is allowing executives to not only maximize their return on automation investments, but also enhance them. For instance, by establishing a Lean production system, executives are systematically removing waste created through overburdened and uneven workloads.

In addition, they are removing costly environmental waste, such as solid/hazardous waste and excess energy or water use. In fact, a recent U.S. Environmental Protection Agency report found that “using Lean principles to improve chemical and waste management processes can have big pay-offs for environmental performance and bottom-line results.”

Ultimately, like automation, Lean manufacturing principles are letting factories produce significantly more with the same or less resources. They are reducing lead time while increasing quality, productivity, on-time delivery, system flexibility and manufacturing capacity—the same benefits promised by automation.