Socks lamination operation – Case #274

November 10, 2014

“A picture is worth a thousand words”. Practical solutions to problems encountered in the manufacturing process that demonstrate how we assist our customers’ factories to produce Right from the Start TM.

Problem: the socks foil lamination operation was not well designed:

– the factory did not have a proper jig

– the marking to maintain the distance of the logo from the raw edge was not adequate

– the socks position marking was not clearly visible

All this resulted in excessive time consumption to place the component on the marking.

Impactiva solution: we got the factory to develop and use a new jig for socks lamination:

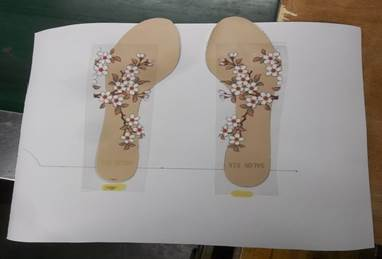

1) The socks position marking and the logo distance from the raw edge were marked on a white pattern board for clear visibility.

2) Double side self-adhesive tape was attached to retain the position of the socks and lamination during pressing.

3) Five sets of jigs were developed to increase productivity.

Stay tuned for more Impactiva technical solutions to every day production problems.