Construction improvement – Case #563

February 24, 2017

“A picture is worth a thousand words”. Practical solutions to problems encountered in the manufacturing process that demonstrate how we assist our customers’ factories to produce Right from the Start TM.

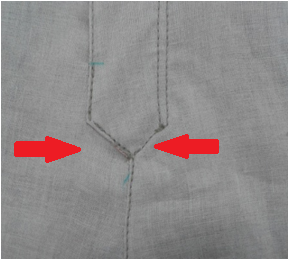

Problem: incorrect stitch shape in a reversible garment. The factory was doing a dummy stitch and the final fly tacking on both sides of the fly at the same time. They had allotted 2 operators for this. With this construction sequence the factory was getting only 25 pieces per hour.

Impactiva solution: we got the factory to eliminate the operation of dummy stitch on both sides of the fly. Then we got them to do the fly tacking stitch on a single layer of face and reverse sides by the same operator. They consequently reduced the machines and man power used for dummy tacking. With this improved construction sequence the factory was able to get 30 pieces per hour, what means a 20% increase in productivity. Note: this solution was provided within our Apparel QA service, this was not a Process Optimization project.

Stay tuned for more Impactiva technical solutions to every day production problems.